News

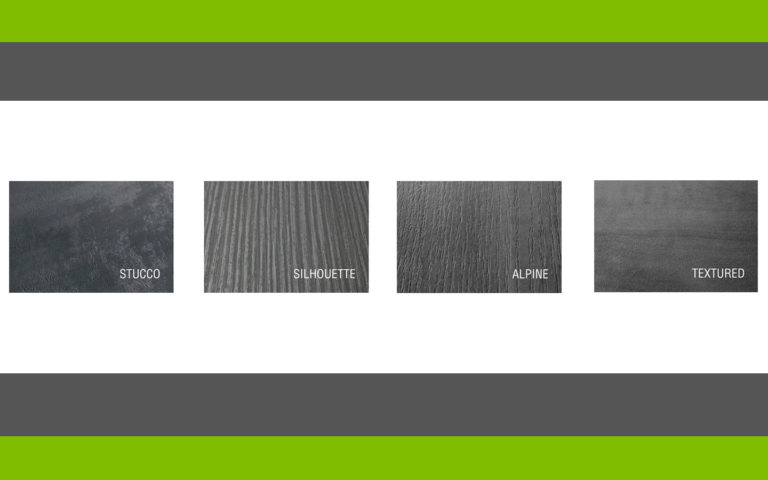

Our finishes: A finish for every decor

Our finishes: A finish for every decor

...

Getting your Sonae Arauco boards: what you need to know

Getting your Sonae Arauco boards: what you need to know

...

These are the décor trends that made waves in Europe this winter

These are the décor trends that made waves in Europe this winter

...

Green Businesses in South Africa

These green South African businesses are making a change for the better when it comes to operating sustainably with as little impact on the environment as possible.

...

International Day of Forests

The United Nations General Assembly proclaimed 21 March the International Day of Forests (IDF) in 2012. The Day celebrates and raises awareness of the importance of all types of forests. On each International Day of Forests, countries are encouraged to undertake local, national and international efforts to organize activities involving forests and trees, such as tree planting campaigns. The theme for each International Day of Forests is chosen by the Collaborative Partnership on Forests. The theme for 2020 is Forests and Biodiversity. (United Nations, 2020) 1

...

Particleboard and MDF

At Sonae Arauco we make our decorative boards out of two different wood-based products, namely Medium Density Fibreboard (MDF) and Particleboard. These wood-based boards form the basis of all our products and so, in this article we are going to look at the two types of boards in more detail in order to give you a better idea of what each product is and the differences between the two.

...

How melamine coated paper is laminated onto boards

Sonae Arauco’s wood-based decorative boards are made of either Medium Density Fibreboard or Particleboard that have been given a melamine finish. We have previously looked at how Sonae Arauco’s wood-based panels are manufactured, as well as the difference between Medium Density Fibreboard and Particleboard; in this article we are going to look at the process in which melamine coated decor paper is laminated onto our wood-based panels to create our wide range of decorative boards.

...

A brief history of melamine-faced boards

We come across melamine-faced boards in all different facets of our lives, from our bedrooms to our kitchens and our workplaces. Thanks to their versatility and wide range of finishes, these decorative boards have cemented their place as décor essentials in any home.

...

Sonae Arauco: about our timber

At the heart of Sonae Arauco lies the timber supply we use to make our Medium Density Fibreboard (MDF) and Particleboard. These boards form the basis of our range of wood-based decorative panels. To give you a better idea of where and how we source our timber, we spoke to Gavin Burnhams – Sonae Arauco’s timber specialist – about this process:

...

Manufacturing melamine boards

We previously wrote an article which looked at the process behind how our wood-based panels are made – from the process of how medium density fibreboard (MDF) and particleboard are made, to the actual process where the melamine facing is applied. What we haven’t looked at, however, is how these wood-based panels are turned into a trendy kitchen cabinet or bedroom cupboard. To give you a better idea of the manufacturing process that melamine boards go through once they have left our factory, we’re going to do a walkthrough of a factory that designs and manufactures a range of products for kitchens and bedrooms, using melamine boards.

The process starts behind the scenes with the designer, who receives plans for the design which includes specifications such as dimensions, colours and the type of board that needs to be used. With that information, the designer will then use specialised software to render 3D images of what the product will look like, including the 3D wire frame and all the information for the finishes. Once the piece has been rendered in 3D then the designer breaks up each piece into the individual parts that will then be assembled and creates a 2D image of each part. Information on each of the pieces and their respective parts, along with any other specifications are then sent by the designer to the factory floor for the production process to begin.

Beam Saw Machine loading area

The manufacturing process begins when the boards are taken to the Beam Saw Machine’s loading area. The Beam Saw Machine is a highly specialised piece of machinery which is programmed for precise board cutting. The fully automated machine is operated by one person who loads the boards onto the machine and then removes them once the boards have been cut according to the exact measurements and specifications sent through by the designer. Once a piece has been cut it is then labelled with a sticker that contains a barcode, which can then be scanned to show the name and description of the piece, as well as what needs to be done with it. This eliminates the risk of error further along the production line as each product is scanned at each machine to tell the machine what needs to be done.

Edge Bander Machine

From the Beam Saw Machine, the cut board is then sent to the Edge Bander Machine. This state-of-the-art piece of machinery is responsible for edging each cut piece of board. The board is fed into the machine which glues on, trims and then neatens the edging, as well as polishing the board once the edging has been applied.

CNC Machine

Once the cut pieces of board have been edged, they are then taken to the fully automated CNC Machine which is where holes are drilled into the board for the dowels. The machine shoots and glues the dowels into the holes which have been drilled into the board. The dowels are used in place of metal nails for the reinforcement and the assembly of the product.

When the dowels have been inserted and glued, the now cut and edged pieces of board are then sent to the assembly line where the parts are sorted, and the individual pieces are glued together by hand to form the final product, such as a kitchen cabinet or bedroom cupboard. Once the piece has been assembled and the glue dried, the product is then carefully wrapped and sent to a waiting area where it awaits transportation.

It is through this process that the wood-based panels which we produce are made into the trendy pieces in people’s homes.

https://www.sonae.projects.coppertable.co.za/

Read our previous article here